Spring plungers from norelem

The extensive norelem range comprises various operating elements, including spring plungers. The operating elements are used in simple clamping applications and positioning work.

Spring plungers perform an important function by absorbing compressive forces and at the same time providing a certain flexibility or resilience. This enables precise positioning of parts in machines and tools, as well as compensation for movements under load or vibrations.

These special components ensure precision and durability in production. They contribute significantly to minimising wear on workpieces and machines.

What are spring plungers?

How do spring plungers work?

What are spring plungers used for?

Application examples of spring plungers

Spring plungers and their versions

Details of spring plungers

Materials of spring plungers

What are the DIN standards for spring plungers?

What are spring plungers?

Spring plungers, also known as spring-loaded plungers or ball plungers, are standardised operating elements used for permanent locking.

They consist of a hollow screw or a press sleeve that contains an integrated spring and a ball or pin. These components offer high precision and repeatability. To use a spring plunger, a suitable thread or hole is required. Once screwed or pressed in, the plunger remains firmly in place.

Spring plungers are mechanical components that are used in various applications. To absorb or exert pressure, or to secure or position things. They are characterised by their resilient properties. This enables them to retract or extend in order to react to external forces.

How do spring plungers work?

Before the plunger is used, it should be installed properly.

norelem spring plungers are available in both press-fit and screw versions. You can use your finger, your hand or a simple assembly aid to press the plunger in. The plunger is then pressed into the mounting hole. The special assembly key for spring plungers is suitable for screwing them in.

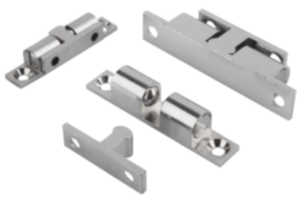

Once installed, spring plungers allow different components to be fixed securely in defined positions in relation to each other. The plungers consist of a sleeve and a pin or ball surrounded by a spring.

In application, one element is held by the spring plunger, while on the opposite side there is a slot or hole into which the locking element engages. Spring plungers can be used to secure an element sliding past, such as a locking pin, for which suitable slots are machined into the pin.

Once they have engaged, ball plungers hold the corresponding components firmly enough to maintain their position in relation to each other even in the event of vibrations.

When the components are actively moved out of the locking position, the ball of the spring plunger presses into the sleeve and releases the lock. When the pressure is released, the ball returns to its original position. This spring-like behaviour makes it possible to fix, position or secure workpieces.

Of importance for the function of spring plungers is the significance of the spring force. The spring plungers are available in various spring force strengths.

Depending on the requirements of the respective application, the appropriate spring force strength should be selected according to the forces acting on the workpiece. For standard applications with smaller or lighter components, the light spring force or the standard spring force is usually sufficient.

Plungers with increased spring force generate a stronger compressive force, which is particularly advantageous when an increased holding force or stronger pressure is required in situations with heavier components or in particularly high-vibration environments.

What are spring plungers used for?

The most typical applications for spring plungers include:

- Locking (clamping and holding) of adjusting elements

- Positioning of workpieces

- Securing of fixture components

- Holding the position of parts by engaging mechanisms

Application examples of spring plungers

Thanks to the wide range of material combinations, norelem’s spring plungers are suitable for almost all areas and applications.

Spring plungers are used in various industrial sectors, including toolmaking and mechanical engineering, precision mechanisms, electronics manufacturing, aerospace as well as medical technology. In these industries, these components ensure the exact positioning and locking of components.

Spring plungers are also used in household appliances such as washing machine knobs and in the automotive sector in cup holders.

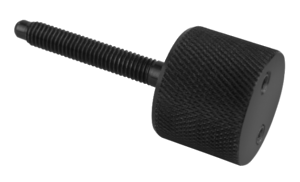

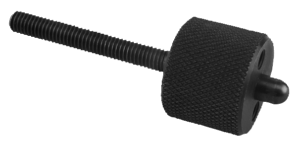

Spring plungers and their versions from norelem

We offer a wide range of spring plungers in various versions to meet the diverse requirements of industry. These spring plungers are available in different sizes and materials to suit different applications.

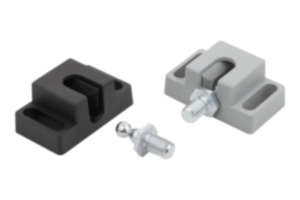

Our range includes spring plungers with both ball and pin.

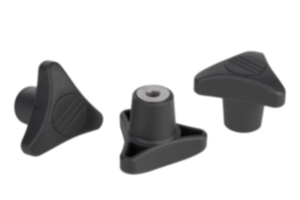

The version with a ball comprises a spring and a ball placed inside a sleeve. The spring generates pressure and the ball serves as a contact or locking point. The ball version enables quick and precise adjustment of parts to fix them in the desired position. This ensures outstanding precision and consistency in production. A spring plunger with ball is suitable for simple clamping and positioning work.

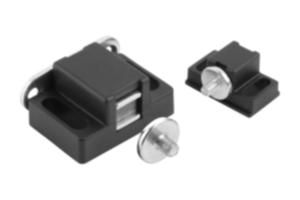

In contrast, spring plungers with pins are equipped with a pin at the end of the sleeve. The thrust pin can be inserted into a corresponding opening or hole in other components to achieve the desired positioning or fixing. This type of fixation is known as locking.

The choice between spring plungers with ball or pin depends on the specific requirements of your application and your design preferences. Both variants ensure precision and repeatability in the positioning of components and your choice may be influenced by which shape is better suited to your particular application.

Spring plungers with ball or thrust pin are often mistakenly referred to as set screws, grub screws or worm screws with ball or thrust pin. It is important to understand that these are different categories of fastening and connecting elements. Spring plungers are specialised components designed to absorb or exert compressive forces in order to position, align or fix components. They differ significantly in function and form from set screws, grub screws and worm screws.

Details of spring plungers

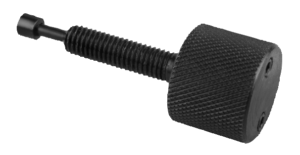

Some spring plungers have a thread lock that prevents unintentional loosening of the plunger. This thread lock is characterised by a notch in which there is an elastically deformable nylon insert. Installation is carried out using either a conventional slotted spanner or an Allen key.

The norelem range includes standardised spring washers in common sizes such as M5, M6, M8, M10 and M12 .

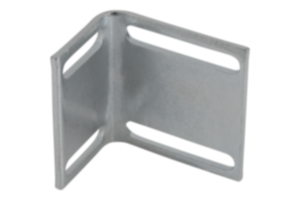

If very precise locking that is resistant to abrasion is required, locators can be used. The combination of a spring plunger with reinforced spring pressure and a locator is suitable for this.

To ensure maximum versatility, spring plungers are available in various materials. It should be noted that many versions are not made entirely from the same material, but instead sleeves and balls or pins are made from different materials. The combination of different materials results in numerous variants from which the right product can be selected for the respective application.

Materials of spring plungers

Plastic spring plungers are characterised by their lightness and cost-effectiveness. They are corrosion-resistant and are therefore suitable for use outdoors or in environments with splash water or high humidity.

Spring plungers with sleeves or balls of steel are designed for applications where high forces or harsh conditions occur. Thanks to the steel production, they are extremely stable and temperature-resistant, which allows them to be used in higher temperature ranges.

Spring plungers with stainless steel parts are characterised by their corrosion resistance. They are also temperature-resistant and lighter than comparable steel models, making them suitable for both higher temperatures and outdoor use.

The balls of spring plungers made of ceramic are extremely temperature-resistant and resistant to chemicals. They also exhibit low wear and are therefore ideal for applications with high cycle rates.

What are the DIN standards for spring plungers?

The DIN standards (German Industrial Standards) are specific standards that define the requirements for various industrial products and processes.

Different DIN standards apply to spring plungers depending on the version and intended use.

Some of the relevant DIN standards for spring plungers are DIN 2093 (disc springs), DIN 1481 (slotted dowel pins) and DIN 6319 (pressure pins).

These standards define sizes, tolerances and technical specifications to ensure that the spring plungers meet quality and performance standards.